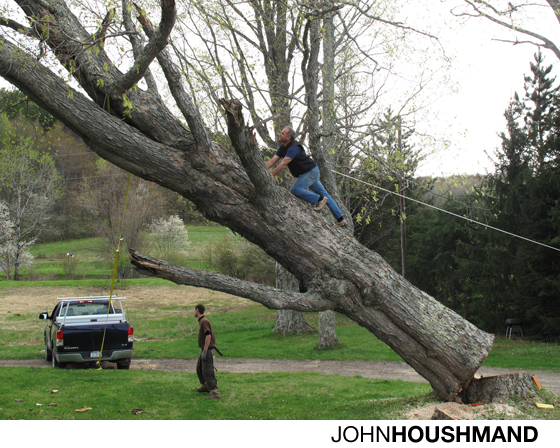

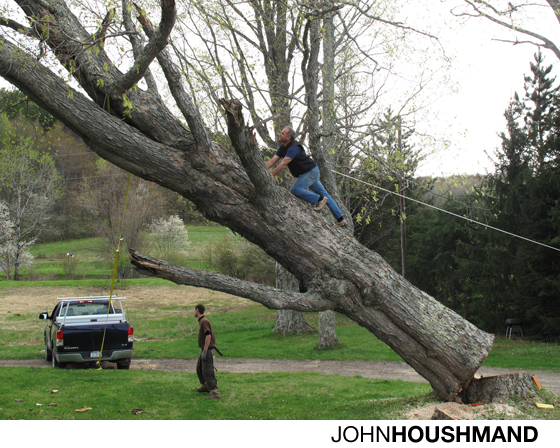

A lot of people ask us about where we get our beautiful slabs of wood, and the answer really is all around. At JOHNHOUSHMAND we don’t harvest wood for our furniture but instead utilize trees that have been felled or damaged by storms, need to be cut down due to safety or otherwise. Hobart, New York really has become John Houshmand’s home and so he is on a first name basis with numerous members of the Catskill community who let him know if they know of any trees that need to be removed.

It’s inspiring to see every part of the process from helping out another in the community, to having some fun climbing the trees, to starting to the create the custom-made furniture that we love to produce.

Our co-workers in the Catskills have been as busy as bees! They have just finished building a new ClearSpan building to store our JOHNHOUSHMAND reclaimed wood slabs. A year ago, a snowfall of an impressive 54 inches caused the roof of one of our smaller slab storage units to collapse. Our entire slab inventory, which consists of thousands, needed to be combined into one cramped center with slab piles stacked at nearly 8 to 10 feet high!

This new building will almost double the storage space we currently have, with an additional benefit: to air-dry slabs in order to shorten kiln-drying time. During a Catskills summer, the heat from the sun on the fabric roof of the building combined with the breeze from open doors allows the slabs to dry quickly yet evenly. We are thrilled that this process will reduce the energy needed to make our beautiful tables, thus making an organic product even greener!

The ClearSpan building is made of galvanized steel frames and a fabric roofing cover. It measures 195 feet long, 55 feet wide, and 22 feet high. Definitely a great sized space to comfortably house our precious organic slabs!

The work we do requires space. Lots of space. That means we need mountains and fields in which to find trees, acres of land to deliver, organize, and mill, tens of thousands of square feet to air dry, store, (and play) and a huge workshop in order to reincarnate these trees as works of art. We happened upon a 30 acre farm, with two 12,000 square foot steel buildings, a hoop structure (read “greenhouse”) for air drying slabs, and a 15,000 square foot concrete slab on which to operate custom sawmills (our sawyers seem to prefer the great outdoors for some reason). With a development loan from the Catskill Watershed Commission we were on our way and converted this crazy place from a dairy farm to a tailor made facility with room for infinite expansion.

The work we do requires space. Lots of space. That means we need mountains and fields in which to find trees, acres of land to deliver, organize, and mill, tens of thousands of square feet to air dry, store, (and play) and a huge workshop in order to reincarnate these trees as works of art. We happened upon a 30 acre farm, with two 12,000 square foot steel buildings, a hoop structure (read “greenhouse”) for air drying slabs, and a 15,000 square foot concrete slab on which to operate custom sawmills (our sawyers seem to prefer the great outdoors for some reason). With a development loan from the Catskill Watershed Commission we were on our way and converted this crazy place from a dairy farm to a tailor made facility with room for infinite expansion.

The work we do requires space. Lots of space. That means we need mountains and fields in which to find trees, acres of land to deliver, organize, and mill, tens of thousands of square feet to air dry, store, (and play) and a huge workshop in order to reincarnate these trees as works of art. We happened upon a 30 acre farm, with two 12,000 square foot steel buildings, a hoop structure (read “greenhouse”) for air drying slabs, and a 15,000 square foot concrete slab on which to operate custom sawmills (our sawyers seem to prefer the great outdoors for some reason). With a development loan from the Catskill Watershed Commission we were on our way and converted this crazy place from a dairy farm to a tailor made facility with room for infinite expansion.

The work we do requires space. Lots of space. That means we need mountains and fields in which to find trees, acres of land to deliver, organize, and mill, tens of thousands of square feet to air dry, store, (and play) and a huge workshop in order to reincarnate these trees as works of art. We happened upon a 30 acre farm, with two 12,000 square foot steel buildings, a hoop structure (read “greenhouse”) for air drying slabs, and a 15,000 square foot concrete slab on which to operate custom sawmills (our sawyers seem to prefer the great outdoors for some reason). With a development loan from the Catskill Watershed Commission we were on our way and converted this crazy place from a dairy farm to a tailor made facility with room for infinite expansion.